Thanks to its tilting vacuum chamber, the model tilt Auto AR219 is specially designed to alllow you to vacuum package large volume and amount of liquid products such as soups, sauces, stews, mash vegetables, pickled foods, etc. All this easily and quickly while avoiding spills from the phase transition of liquid which appears under "sous vide". Your team will now be able to vacuum package liquid produtcs in a fast, easy and safe routine. Our tilt model has shown to be a very reliable a consistent workhorse for non-stop production of elaborated products while offering simplicity of use and ease of maintenance. The tilt model Auto AR219 is a perfect fit for the packaging of a wide variety of products thanks not only to the large chamber and pump high capacity considering the machine size, but also to the many controls of vacuum and map processes availables. Besides, the tilt model can integrate specific options for liquid products packaging such as a splash filter for the pump and, of course, the model can easily integrate the same options that all our other models have such as gas flush, heavy duty and air assited sealing and soft air return.

Furthermore, the Auto Tilt AR219 model can also perform specialized vacuum packaging processes.

With plenty of working space for a table-top model, the chamber is designed roomy with 7.25" height to fit large cuts and a variety of products.

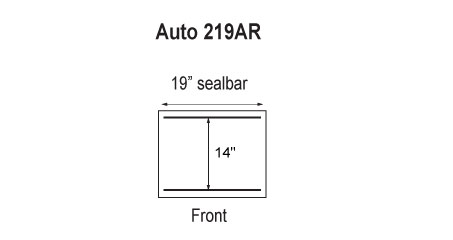

Besides, the dimensions with 19" sealbars are also designed for maximum arrangments of various North American pouches size.

With the included easy set-up support and adjustable shim for liquid products the manipulation of pouches becomes fast and easy.

The dome lid is designed with a wide 65 ° opening to faciliate fast loading and unloading of pouches.

The whole see-through lid allows you to easily watch your pouches and have an unobstructed visual control of your complete packaging process.

Auto-process ensures that you get constant results no matter the size or the quantity of products you are vacuum packaging.

The Auto-vacuum mode performs a complete MAP or full vacuum packaging process smartly. Whatever is your product, the Hi-Tech Auto series machines adjust the running process entirely by itself to ensure that you get the result you want, thus letting you more time working and concentrate on other important tasks.

Memorizing up to 15 dfferent programmable settings for your specialized products.

Auto-cleaning process helps you keep your unit and pump at their optimized performance and extend their life.

Our Auto Series smart algorithms and sensors provide you high accuracy in every subtlety of the process to assure that you get the results you really want, whether it is for full vacuum or modified atmosphere applications.

For more general applications, you may want to explore our time-based measurement process Nel Series.

Our Auto Series smart algorithms and sensors detect the transition phase of your liquid products during the vacuum cycle and determine the best moment to complete the vacuum cycle, just before a spill can occur.

Therefore, you are not only avoid liquid spills inside your chamber, but you are as well assured to have removed a maximum quantity of air from your liquid products.

| Model Tilt Auto AR219 | |

|---|---|

| Electrical requirements | 120V, 1, phase, 60 Hz |

| Busch pump | 24 m3/h, 1.25 HP |

| Vacuum level | up to 2 mbar |

| Oxygen O2 evacuated proportion at 2 mbars | 99.999% |

| Sealing bar(s) | 2 x 19" |

| Distance between the sealing bars | 14" |

| Chamber height | 7.25" |

| Overall dimension | 26"x 27.5" x 55" (lid opened) |

| Ready for gas flush option | Yes |

| Warranty | 1 year |

General and versatile modified atmosphere and vacuum packaging.

Advanced and refined MAP and vacuum processes.

Vacuum packaging in high volume and high production rate.

Compact and mobile for side production or individual portions.